Expansion Project of the World's Largest Single-Factory Cathode Production Facility

The POSCO Group is the sole global entity equipped with a comprehensive supply chain, offering everything from raw materials for secondary battery components (such as lithium and nickel) to final materials, including cathode and anode materials.

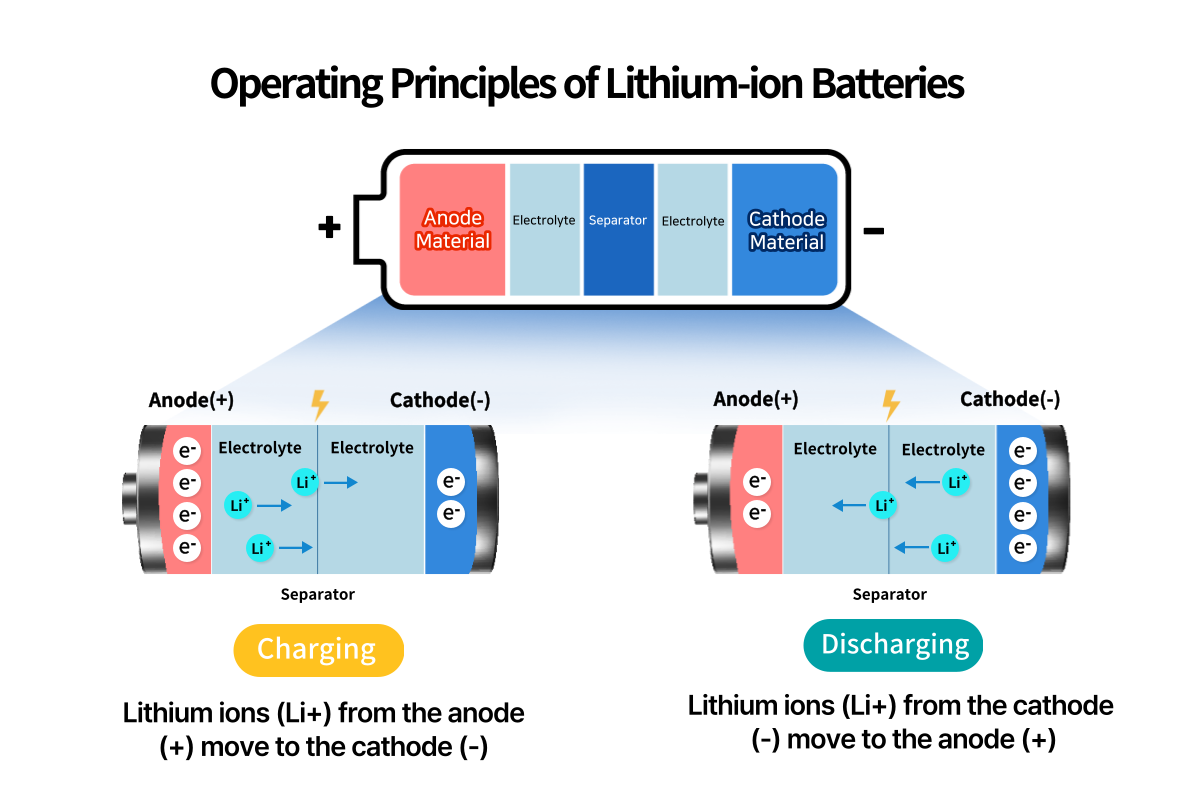

The lithium-ion battery, a dominant player in the current battery market, comprises four integral elements: the cathode, anode, electrolyte, and separator. It is a device that efficiently transforms chemical energy into electrical energy through an 'oxidation-reduction reaction' involving the cathode (+) and anode (-) substances.

Put simply, when lithium-ions from the cathode shift to the anode, the battery charges. Conversely, when lithium ions from the anode migrate back to the cathode, the battery discharges.

* Oxidation-reduction reactions are interactions that arise from the 'electron (e-) movement' between reactants, with the electron-releasing side being 'oxidized' and the electron-gaining side being 'reduced’.

The cathode material is a key element that governs the 'capacity' and 'voltage,’ both of which are critical to battery performance. As a result, the cathode material market is projected to soar at an average annual rate of 33%, escalating to a volume of 2.75 million tons by 2025 due to burgeoning demand in the electric vehicle and energy storage system sectors.

POSCO FUTURE M's Gwangyang Cathode Plant stands as the world's largest cathode production plant housed within a single factory, boasting of an annual production capacity of approximately 90,000 tons of cathode material. Of this total, POSCO E&C has contributed an additional capacity of 85,000 tons through the successful expansion of stages 2, 3, and 4.

In response to the quickening demand surge for cathode materials, POSCO E&C has pioneered a Smart Construction system for expeditious factory expansion. By leveraging pre-construction (Pre-con) strategies, Big Room meetings, the application of Building Information Modeling (BIM), and robust collaboration with POSCO FUTURE M, the company has preemptively simulated factory interferences, thus minimizing process loss.

By incorporating a flame-retardant panel developed in collaboration with POSCO and utilizing Pos-H Beam, PosMAC, and POSCO Yamato VINA section steel materials, the factory has also significantly improved safety and quality, optimally leveraging group synergy.

In essence, the Gwangyang Cathode Plant, as POSCO E&C's initial and largest achievement in cathode factory construction, signifies a pivotal milestone for the firm's endeavor to ascend as a global EPC leader in the realm of secondary battery materials.